Bio Concrete Admixture

1. Preface

BioconcTM is a liquid bio-technological product, made from natural organic material, protein denaturation, biopolymer surfactant and organic mineral , which is fermented by several microbe. Based on the various performance of those several microbes, then produced several Product Variants of Bioconc TM, consist of the following products : Bioconc_07TM, Bioconc_08TM , Bioconc_09TM

2. Background

In the construction worlds, major construction component is reinforced concrete structure. This is caused by the economical aspect and flexibility to be formed of the reinforced concrete structure, due to the Architectural Design.

The Concrete material components are consist of Portland Cement, whether OPC (Ordinary Portland Cement) or PPC (Puzzolanic Portland Cement), Coarse Aggregate, Fine Aggregate , Water and Concrete Admixtures for any purpose.

Concrete Admixtures Classification based on the ASTM C-494, consist of 7 Types as described follows :

Type A : Water Reducer (WR)

Type B : Retarder

Type C : Accelerator

Type D : Water Reducer Retarder (WRR) : Water Reducer Accelerator

Type E : High Range Water Reducer

Type F : High Range Water Reducer (HRWR)

The optimum Admixture content regulated based on the concrete cement content based between 1,4% – 2,4% from the weight of cement. By using of optimum concrete admixtures, yield the best interaction between cement and admixtures (Wille cs,2011)

All of those type, based on the chemical based, and should be handled carefully based on the cement content, and should not be exceeded from 1,4%- 2,4%. Negative point of the using of the chemical based admixtures is rise serious problem on the treated concrete, for instance whenever the dosage of Super plasticizer more than specified, the concrete will not bound or well known as “Long Setting”, which is will disturbed the overall building construction sequences.

3. Bioconc – Bio Chemical Based Concrete Admixtures

Bioconc Products Series are bio chemical based concrete admixtures. which is have each specific concrete qualities treatment as described follows :

Bioconc-1 : Raw Material – not for sale

Bioconc-2 : Raw Material – not for sale

Bioconc-3 : Raw Material – not for sale

Bioconc-4 : Raw Material – not for sale

Bioconc-5 : Raw Material – not for sale

Bioconc-6 : Raw Material – not for sale.

Bioconc-7 : Specified to treat as micro-filler and functioned to reduced cement content up to 35% on concrete mix with survi- ved strength event increase compared with regular mix concrete, and depend on material properties of concrete rawmat.

Bioconc-8 : Perform as Self Healer Concrete Admixtures

Bioconc-9 : Concrete Integral Watertight Bio-admixtures

The Bioconc Product series will be developed and added as the future concrete bio-admixtures requirements and our research & development. Basically the aplication of Bioconc Product series are based on concrete volume based (not cement content based). The recommended dosage is between 400 cc – 550 cc each m3 concrete volume. The optimum dosage is 500 cc / m3 concrete volumes.

3.1. Bioconc -07TM Concrete Admixtures – Micro Filler & Strength Increaser

Product Variant Bioconc_07TM with microbe perform to produce mycelia as microfiller on Concrete Mix, Bioconc_07TM inserted the micropores between coarse and fine aggregates which is usual filled by cement paste, so required cement paste reduced, while the bonded aggregate surface represented by Finenes Modulus greater than regular concrete, treat the strength of concrete event better. This phenomenon rise the cost saving of concrete cost production.

3.2. Bioconc -08TM Concrete Admixtures – Self Healer Concrete Bio Admixtures

Product Variant Bioconc_08TM with microbe perform to produce urease enzyme as soon as activated after to be supplied oxygen from the initial crack of concrete (initial condition this microbe dormant in setting concrete {oxygen blocked after concrete setting time}). Later on, urease enzyme react to the existing water/humid and calcite surround the cracked concrete produce CaCO3, then the cracked concrete healed (self healing), with the following mechanism :

On initial cracked, oxygen supplied inside cracked concrete and activate the dormant microbe produce “urease” enzyme, react to water on cracked concrete :

(NH2)2CO + H2O = CO3-2 + 2NH4+

Urease Enzyme + Water = carbonate + 2 moles ammonia

React to the Oxide Calcium/Calcite ( CaO ), form the following reaction :

CO3-2 + 2NH4+ + CaO —> CaCO3 + NH3 + H2O

Self Healing

3.3. Bioconc -9 Concrete Integral Watertight Bio Admixture

Product Variant Bioconc_09TM with microbe perform as integral bio-watertighness on concrete mix, Bioconc_09TM. The Performance of Bioconc_09TM has been applied and proven worked on following several project

- Ground Tank Restaurant Lie – Malang.

- Ground Reservoir Kantor Pusat Dakwah – Ambon.

- Ground Tank SDIT Cendekia-Ambon.

- Mock Up Mass Concrete Semantok Dam Project – Nganjuk, end of 2020.

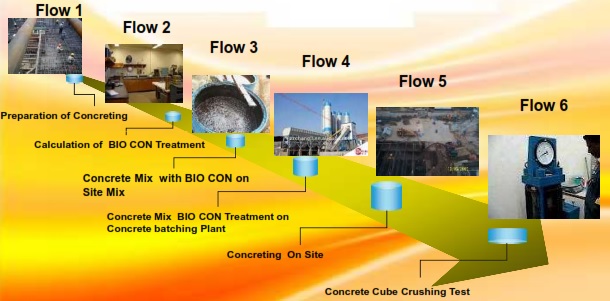

4. Comparison Between Regular Mix & Concrete-Bioconc Mix

The Job-mix comparison between Concrete Regular Mix vs Concrete- Bioconc mix and its compressive strength results as described on the following tables :

5. Conclusion

Bioconc Product Knowledge Bio-Chemical Based Concrete Admixtures

Bioconc-7 works to reduce cement content of a regular jobmix up to 30%, with the concrete strength result higher than sepcified jobmix concrete qualities.

The optimum dosage of Bioconc-7 every m3 concrete volume is 500 cc. may increase the concrete strength up to 34% compared to specified concrete jobmix.